Like any other structural assembly, fasteners play a critical role in the smooth functioning of solar installations. Fasteners hold parts together and must maintain their performance over many years under changing weather conditions. But the fact that a bolt is designed to be disassembled can pose serious challenges soon after, failure to arrest unwanted loosening of a fastener means frequent and expensive re-torquing during periodic maintenance and even catastrophic failures in case of neglect.

A variety of reasons can cause threads to loosen resulting in loss of clamp load on assembly. Vibrations, thermal changes, gasket relaxation, improper on-torque, shocks and impact load all can lead to stress that can force unwanted movement between threaded joints. This happens due to gap between threads. Over a period of time loosening under adverse conditions nevertheless is a reality for all fasteners.

To quantify the locking abilities of commonly and traditionally used locking methods, we did few laboratory tests under lab conditions to demonstrate how these traditional methods lock.

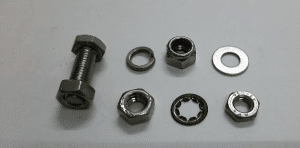

Commonly used locking devices

Torque Meter

The table below lists (Titled: Torque retention behaviour in static condition) torque loss values in an M8 (Grade Stainless Steel) fastener locked using mechanical locking methods and tightened to 18N-m and tested for unscrewing torque after 48hours.

| S/N | Name of locking method | Locking Torque (N-m) | Loosening Torque (N-m) | Torque Augmentation |

|---|---|---|---|---|

| 1 | Without locking method | 18 | 10 | (-44%) |

| 2 | Split ring washer | 18 | 10 | (-44%) |

| 3 | Serrated tooth washer | 18 | 13 | (-27%) |

| 4 | Nyloc Nut | 18 | 14 | (-22%) |

| 5 | Double lock Nut | 18 | 12 | (-33%) |

Torque retention behaviour in static condition

As derived above, under laboratory environment mechanical locking method lose their locking torque to frictional losses to the tune of 22- 44% within 48hours. Over a period of few months and in real life environmental conditions, the losses can be as high as 80 to 90%, practically leading to very little clamping force over the panels. Under high wind speed such an assembly can easily give way leading to safety concerns and high replacement cost.

One can also not overtighten SS fasteners (including other soft metals) for the fear of fastener failure or cold welding rendering the fastener permanently fixed with little or no possibility to disassemble in future, an undesirable situation to be in.

Locking of fasteners thus require careful analysis of intended application, right tools, correct level of torquing and a locking method that will stay reliable for the entire life time of the project.

The results in Table above indicates how common mechanical locking methods are inadequate. They just don’t develop enough friction to arrest loosening even when not exposed to vibrations.

So, If one or more of these are your current locking methods, it is time to look beyond and evaluate Chemical locking through Loxeal 86-55 and find performance that far exceeds the conventional, stay same for years and costs only a fraction.

Lets look at how Loxeal 86-55 perform under same conditions

| S/N | Locking method | Tightining Torque (Nm) | Loosening Torque (Nm) | Torque Augmentation (%) 48hours |

|---|---|---|---|---|

| 1 | Loxeal 86-55 Thread locker | 18 | 25 | +39% |

Loxeal 86-55 is allowed to cure for 48hours prior to testing

While most mechanical locking devices lose on-torque to friction, Loxeal 86-55 augments it. Higher the on-torque, higher will be unscrewing torque. Loxeal is a special anaerobic Thread-Locker offering high strength on less active substrates and even in applications of small contact surface area without the use of Activator. It is single component making it very easy to use, room temperature curing and highly resistant to heat, vibrations, water, gases, oils, hydrocarbon and many other chemicals.

A drop of it is just right enough for a life time of reliable performance.