Industry background

In the realm of sealing threaded joints, traditional methods like Teflon tape is becoming obsolete. Anaerobic Pipe Thread Sealant has emerged as a revolutionary alternative, surpassing the limitations of Teflon tape.

End Product: Induction Heating Machineries

The customer is a renowned induction heating machinery manufacturer, providing industrial heating equipment such as induction heating machines, hardening machines, tube welders, etc. to various OEM’s in automotive, wind energy, healthcare, and general industry.

Current Challenges

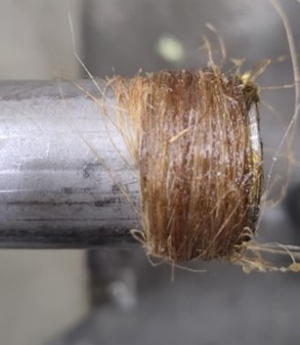

The customer was using the conventional thread sealing method of sealing by using hemp to seal threaded joints starting from ½ inch up to 2 inches. As shown in the picture below, sealing using the hemp method was a very messy, lengthy, and cumbersome process. It requires first application of grease over the thread, followed by positioning hemp and again applying grease over hemp to achieve a proper seal. Despite this laborious process, the sealing was never 100% due to the requirement of highly skilled manpower. Further grease application by hand was not a desirable situation considering the operator’s health and safety.

Elixir Solution

Upon a customer request for a suitable solution to the current challenges, Elixir application engineer visited to plant, studied the application, and suggested to use Loxeal 58-11, a medium-strength anaerobic thread sealant that can be used on metal pipe fitting, stating from 1/4 , up to 2 inch pipe fittings. Loxeal 58-11 is a universal sealant that can seal both pneumatic and hydraulic joints and has various approvals for usage in fluid lines such as incidental food contact, drinking water contact, gasoline and hydrogen lines.

Product Testing and Validation

Pipe fitting of MS fitting up to 2” were sealed using Loxeal 58-11 and subjected to water pressure up to 60 bar after 8 hours of curing. It was observed that there was no leakage and the product performance was found to be satisfactory. The customer was delighted to see the ease with which the application was done and with “zero” rejections, and decided the implement Loxeal 58-11 for thread sealing application across the product line.