Adhesives today are as much an important assembly method as fastening, riveting or welding. One glance around and there are numerous products that are made more reliable, efficient and beautiful through adhesive technology. From aerospace to automobiles, appliances to handheld devices and every kind of engineering product, adhesives are there everywhere working their magic silently.

Applications of adhesives are constantly evolving and with the introduction of newer and more advanced formulations, they are used in some of the most challenging industrial applications. Bonding prior to powder coating is one such application. While adhesives have always been used to bond parts post paint baking process, adhesive bonding prior to powder coating must overcome few critical demands.

- Adhesive must be able to withstand the rigours of high temperature and aggressive chemical wash process prior to powder coating.

- Conduct sufficient enough electricity for electrostatic spraying of powder coatings.

- Must hold the coating powder to itself to allow for even colour distribution.

- Most assembly line require fast processing. The said adhesive must cure quickly and develop chemical and temperature resistance rapidly.

- Adhesive must be able to withstand the baking cycle that can be as high as 200°

Till not long ago this was thought only possible through welding and other conventional processes and designers and process engineers had to manage problems such as:

- Warpage and part distortion

- Introduction of additional processes like grinding, buffing and polishing.

- Aesthetically unappealing products.

Think of applications like metal cabinets, stiffener joining, signage boards, architectural panels and more. With Elixir’s structural bonders, EL-801PC and EL-804PC it is not only possible to bond metals prior to powder coating but the entire assembly time can be as quick as conventional methods if not faster.

EL-801PC and EL-804PC are structural adhesives formulated for applications that require replacing mechanical assembly methods without the use of expensive curing or processing equipment. They cure at room temperature and develop unitizing bond rapidly.

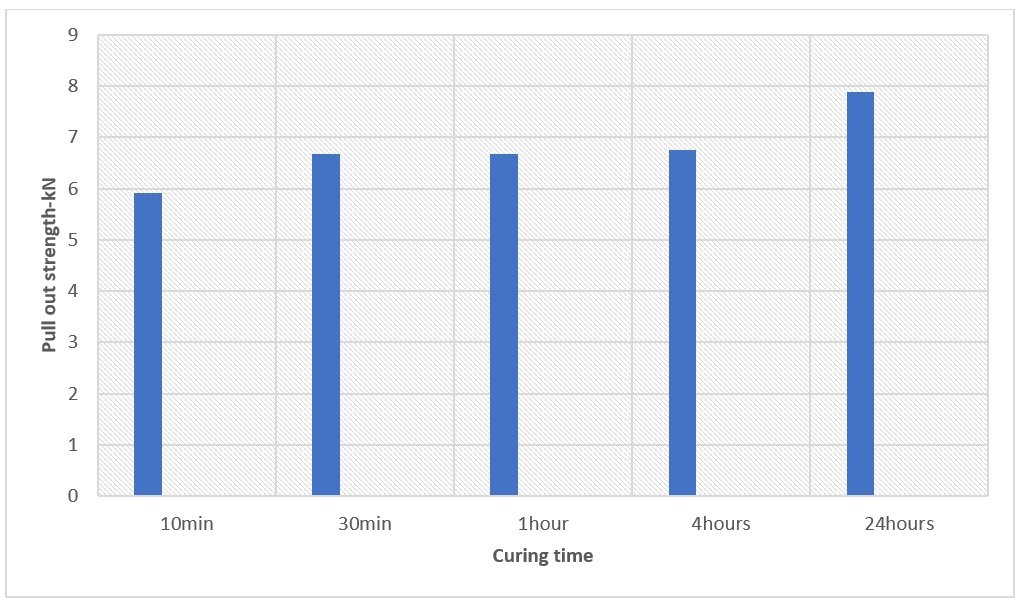

The graph below indicates pull out strength of bonded lap joints on mild steel at different cure time (cure time allowed post application and prior to exposure to wash cycles) and 200°C oven temperature for 20minutes.

Consult us for your bonding needs [email protected]