About this blog

This writeup is an extract of a study being conducted at Elixir-India about bonding or gluing Polypropylene. Our finds will also help in successful bonding when working with PE,PTFE,HDPE or LDPE.

How this writeup can help

Polypropylene is one of the most commonly produced and used thermoplastics in the world.It is known for its good mechanical properties, heat and chemical resistance and also has excellent moisture resistance. Due to these advantages it is widely used for packaging consumer products, plastic parts for industries, textiles and many special devices.

But Polypropylene has a rather slippery surface which makes it difficult to bond to itself or to other surfaces using adhesives. Our study can help designers and manufacturers understand new and innovative methods and products to successfully form durable adhesive bonds when working with Polypropylene which otherwise seems a daunting task.

Why is it difficult to bond Polypropylene.

Polypropylene has a slippery or slightly lubricating surface (similar to PTFE).It makes it difficult for most adhesives to wet its surface properly or to penetrate the surface to form a mechanical locking.

The wettability of a surface can be defined in terms of its surface energy. Higher the surface energy better is wettability or its bond ability.

Lets look at the surface energy of some of the most common industrial substrates.

As the table shows, metals have the highest surface energy followed by plastics and PP has one of the lowest surface energy among all plastics.

Since most adhesives have a surface energy in the order of 40 dynes / cm2, Polypropylene having the surface energy in the less than 30 dynes/cm2 are always a challenge while bonding.

PP Bonding adhesives:

Traditionally Hot melt adhesives have been successfully used for bonding PP and other low surface energy plastics in addition to Thermal bonding and Ultrasonic welding.

In this article, however, we will look at two of the more versatile product groups that bond rapidly and forms durable bond without any special surface preparation.

Cynoacrylate adhesives (CA):

Instant adhesives (also known as CA) are known for their high performance on plastics and elastomers but they do not form strong bonds on Polypropylene substrates when used as a standalone solution.

Consider below the lap shear strength of a high performing Loxeal Instant Adhesive (Loxeal 43S) when used to bond.

| Plastic Type | Bond Strength |

|---|---|

| Unfilled PP | 3.00 Kgf/cm2 |

| Unfilled PP roughened using sand paper | 3.00 Kgf/cm2 |

Roughening has slight improvement in the bond strength due to increase surface area but it does not add much in practical terms.

Now, lets look at how the strength can be increased significantly by increasing the surface energy of PP using Loxeal Primer-7.

| Plastic Type | Bond Strength |

|---|---|

| Unfilled PP | 34.00 Kgf/cm2 |

When the same high performing Loxeal 43S is used after activating the PP surface with Loxeal Primer-7, the bond strength goes up over 10 times.

Twisting force resistance:

A PP lapshear joint primed using Loxeal Primer-7 and bonded with Loxeal 43S develops very good resistance against twisting force with 25mm to 10mm overlap joint and fails in adhesion mode.

Under 10mm overlap strength drops significantly and fails in adhesion mode.

Peel force resistance

As in case of twisting action, a combination of Loxeal Primer 7+Loxeal 43S also develops very good resistance against peel force with 25mm to 10mm overlap joint and fails in adhesion mode.

Under 10mm overlap strength drops significantly and fails in adhesion mode.

Two component acrylic adhesive (PP Bonders):

Under this category, three products have been designed to outperform the performance of every other adhesive when bonding PP and other low surface energy surfaces.

| Product Name | Fixture Time-min | Unique feature |

|---|---|---|

| Loxeal 3460 | 5-8 min | Glass filled for gap control |

| Loxeal 3461 | 10-15 min | Glass filled for gap control |

| Loxeal 5465 | 6 min | For zero gap joints |

Lets now look at their performance when bonding unfilled PP

| Product Name | Bond Strength |

|---|---|

| Loxeal 3460 | > 41 kgf/ cm² * |

| Loxeal 3461 | > 41 kgf/ cm² * |

| Loxeal 5465 | > 41 kgf/ cm² * |

*Indicates substrate failure

Twisting force resistance:

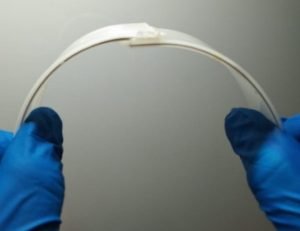

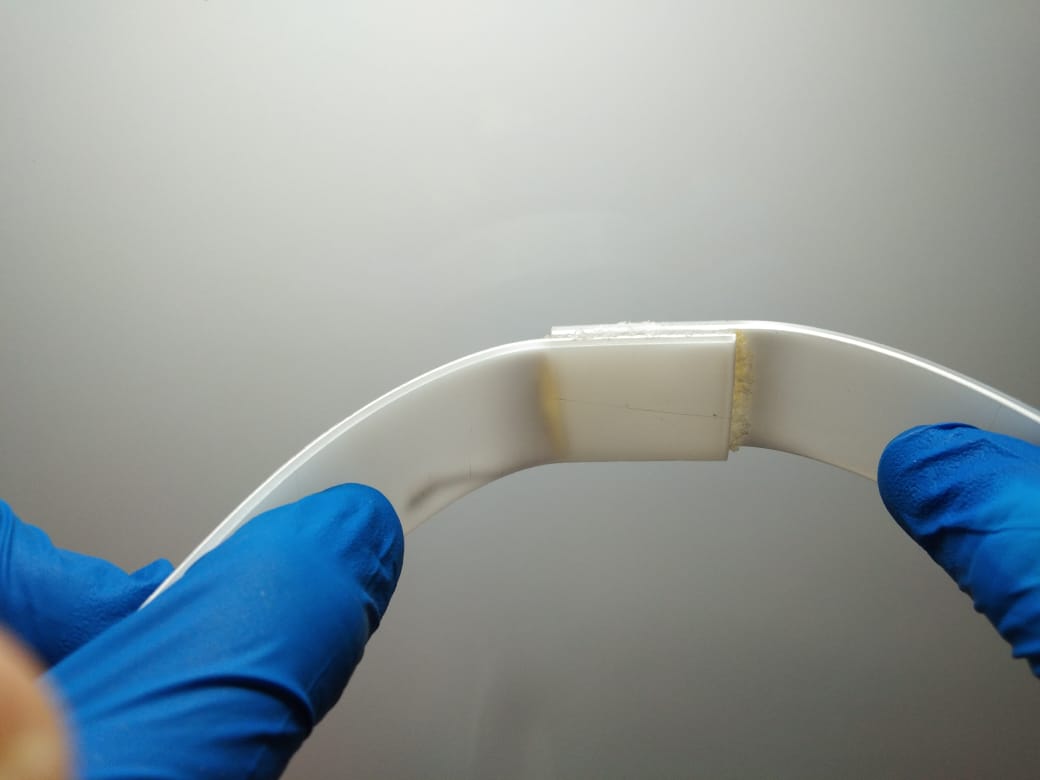

A PP lapshear joint bonded using above Loxeal grades develop excellent twisting force resistance between 25mm to 10mm overlap, resulting in substrate failure.

Joints between 10mm to 5mm overlap bond exhibits very good resistance too and fails in cohesive mode.

Peel force resistance:

As in case of twisting action, a PP lapshear bonded using all the above Loxeal Acrylic Adhesives develop excellent peel force resistance between 25mm to 10mm overlap, resulting in substrate failure.

Joints between 10mm to 5mm overlap bond exhibits very good resistance too and fails in cohesive mode.