It is a known fact that a dispenser or caulking gun as it is widely called plays an important role in finish and productivity while applying the sealants. But to what extent it impacts these parameters is hardly a factor deeply looked into by most users.

This article is an abstract of a study conducted at Elixir-India to assess the performance of different types of dispensers while using a gun grade paste sealant in terms of time they take and finish generated.

Sealant Used

The choice of sealant is Silane Terminated Polymer (STP) of high paste consistency Sikaflex 521UV Grey in a 300ml cartridge.

Dispensers evaluated

The dispensers evaluated are of 300ml capacity as follows

| Dispenser Name | Type | Advantage Ratio |

|---|---|---|

| Locally available caulking gun | Manually Operated | Not known |

| Easiflow HD | Manually Operated | 7:1 |

| Midiflow Cartridge | Manually Operated | 10:1 |

| Powerflow HP Cartridge | Manually Operated | 18:1 |

| Ultraflow Cartridge | Manually Operated | 25:1 |

| Airflow 3 Cartridge | Pneumatically Operated | Not applicable |

| Easipower Plus Cartridge | Battery Powered | Not applicable |

Test method

Each dispenser was used to apply the same cartridge of Sikaflex521UV to generate a bead of 3mm diameter and 1 meter in length.

Application time and finish developed is closely monitored and reported against each dispenser.

| Dispenser Name | Type | Advantage Ratio | Air Pressure | Application Time (seconds) |

|---|---|---|---|---|

| Locally available caulking gun | Manually | – | – | 160 |

| Easiflow HD | Manually | – | – | 75 |

| Midiflow Cartridge | Manually | – | – | 49 |

| Powerflow HP Cartridge | Manually | – | – | 32 |

| Ultraflow Cartridge | Manually | – | – | 21 |

| Airflow 3 Cartridge | Pneumatic | – | 5bar | 9 |

| Easipower Plus Combi | Electrical | 1 | – | 11 |

| Easipower Plus Combi | Electrical | 3 | – | 5 |

| Easipower Plus Combi | Electrical | 6 | – | 3 |

| Easipower Plus Combi | Electrical | 9 | – | 2 |

Summary of the result is tabulated above.

The data above quantifies the time it takes to apply the sealant per meter using different types of handheld dispensers. The results can now be deciphered and based on the performance of each type users can better arrive at application specific product selection, also described in this article.

Manual Dispensers

Manual dispensers come in a wide variety of build types and at different price points. The most important aspect to look for in them is “advantage-ratio”. A “low-advantage” ratio means less power and higher “advantage-ratio” indicates high powered dispenser. Now let us look at the four (04) manual dispensers and their advantage ratios.

| Product Name | Type | Advantage Ratio | Application time- 1meter in seconds |

|---|---|---|---|

| Local caulking gun | Manually | Not known | 160 |

| Easiflow HD | Manual | 7:1 | 75 |

| Midiflow Cartridge | Manual | 10:1 | 49 |

| Powerflow HP Cartridge | Manual | 18:1 | 32 |

| Ultraflow Cartridge | Manual | 24:1 | 21 |

Productivity: A high powered dispenser like Ultraflow Cartridge takes about nine times lesser time than a low priced DIY dispenser often available in any hardware shops thus reducing labour cost by more than half and at the same time providing least level of fatigue and improving worker’s morale and work satisfaction.

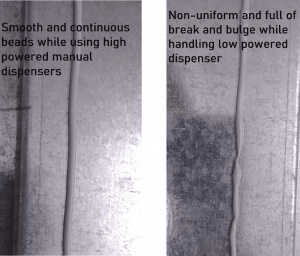

Finish: If finish is an important criterion of the application, a hand gun of 18:1 advantage ratio or above provides uniform and continuous bead for continuous application due to lesser fatigue factor.

Recommendation:

Local caulking gun: Should be limited to small onetime jobs or DIY applications.

Easiflow HD: Can be used for low viscous sealants that are easy to dispense.

Midiflow Cartridge: This dispenser can be used on low to medium viscous sealants for regular or continuous jobs in general industrial setting.

Powerflow HP: It is recommended to use for medium to high viscous sealants for high volume of application on continuous basis such as bus body and railway coach.

Ultraflow Cartridge: This product can be ideally used for high or very high viscous sealants that are otherwise not possible to apply using most other manual dispensers.

Air operated Dispensers

| Product Name | Type | Bead Size | Bead Length | Air Pressure | Application Time (seconds) |

|---|---|---|---|---|---|

| Aiflow 3 Cartridge | Pneumatic | 3mm | 1 meter | 5bar | 9 |

Productivity: No doubt with the result observed that this dispenser is one of the fast-acting sealant hand guns among all types and that offers very high production levels. It is easy to control and output can be further increased by increasing input air pressure upto 6bars.

Finish: Airflow-3 Cartridge provides bubble free, break-free and uniform application of sealant throughout which is critical for best surface finish.

Recommendation: Airflow 3 Cartridge is recommended in high-speed assembly lines either by semi-automatic or fully automatic application methods. It can also be used on every other manufacturing or maintenance set up where faster rate of application is needed.

Drawback: It needs a compressed air line

Battery powered Dispensers

| Product Name | Type | Bead Size | Bead Length | Speed setting | Application Time (seconds) |

|---|---|---|---|---|---|

| Easipower Plus Combi | Electrical | 3mm | 1 meter | 1 | 11 |

| Easipower Plus Combi | Electrical | 3mm | 1 meter | 3 | 5 |

| Easipower Plus Combi | Electrical | 3mm | 1 meter | 6 | 3 |

| Easipower Plus Combi | Electrical | 3mm | 1 meter | 9 | 2 |

Productivity: As can be noticed, these dispensing guns are very powerful. Even at their lowest speed the flow of sealant is very high. Practically they are not feasible to apply thin beads of 3mm beyond the “speed setting 3” because an applicator cannot practically control the flow at those levels.

They are ideal for application of larger beads of around 4-6mm in high volume applications.

Finish: Easipower Plus Combi dispensers offer perfectly smooth finish and they excel in this parameter.

Recommendation: They are ideal in applications where compressed line is not easily available or for applications at a height like building construction, windmill applications and many more.

Drawback: Slightly heavier. Difficult to control the speed of flow for very thin bead applications (<4mm).

Conclusion: The choice of a dispenser has significant impact on running cost and finish of parts at the same time affecting worker’s productivity. Users should carefully make product selection depending on sealants viscosity and desired output.